About OXE Diesel Outboard Engines

- Introduction

- Key advantages

- Performance

- Emissions

- The Design

- Diesel Engine

- Transmission

- Serviceability

Introduction

Introduction

ABOUT OXE DIESEL

The OXE Diesel is designed and built for commercial users. Endurance, reliability, power and control is key. The world’s first commercial diesel outboard combines the reliability and endurance of marine inboards with the flexibility and agility of outboard engines, offering unprecedented efficiency, range and torque.

Our product name OXE pronounced ['əʊ, 'eks, 'i:] (swedish for ox) reflects the fundamental concepts from which this product has been developed - Endurance, reliability, power and control – all significant attributes of an ox. Using OXE as the product name also pays tribute to the hard work, time, stubbornness and relentless effort our team has spent to fulfil the demands of the commercial marine market when inventing the OXE Diesel - worthy of end users trust.

The patented technology of the OXE Diesel provides a robust drive unit that effectively transfers high torque diesel power from the engine to the propeller. Combined with an innovative modular layout, easily accessible service points, closed coolant system, interchangeable gear ratios that allow the user to choose between high torque or high speed and proven diesel technology from the automotive industry, the OXE Diesel is designed and built for commercial use.

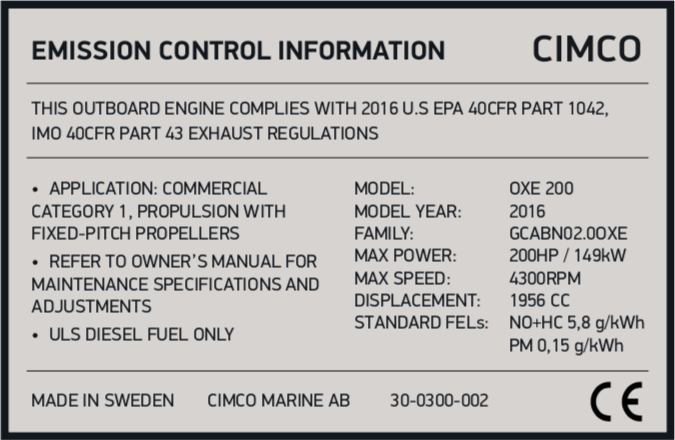

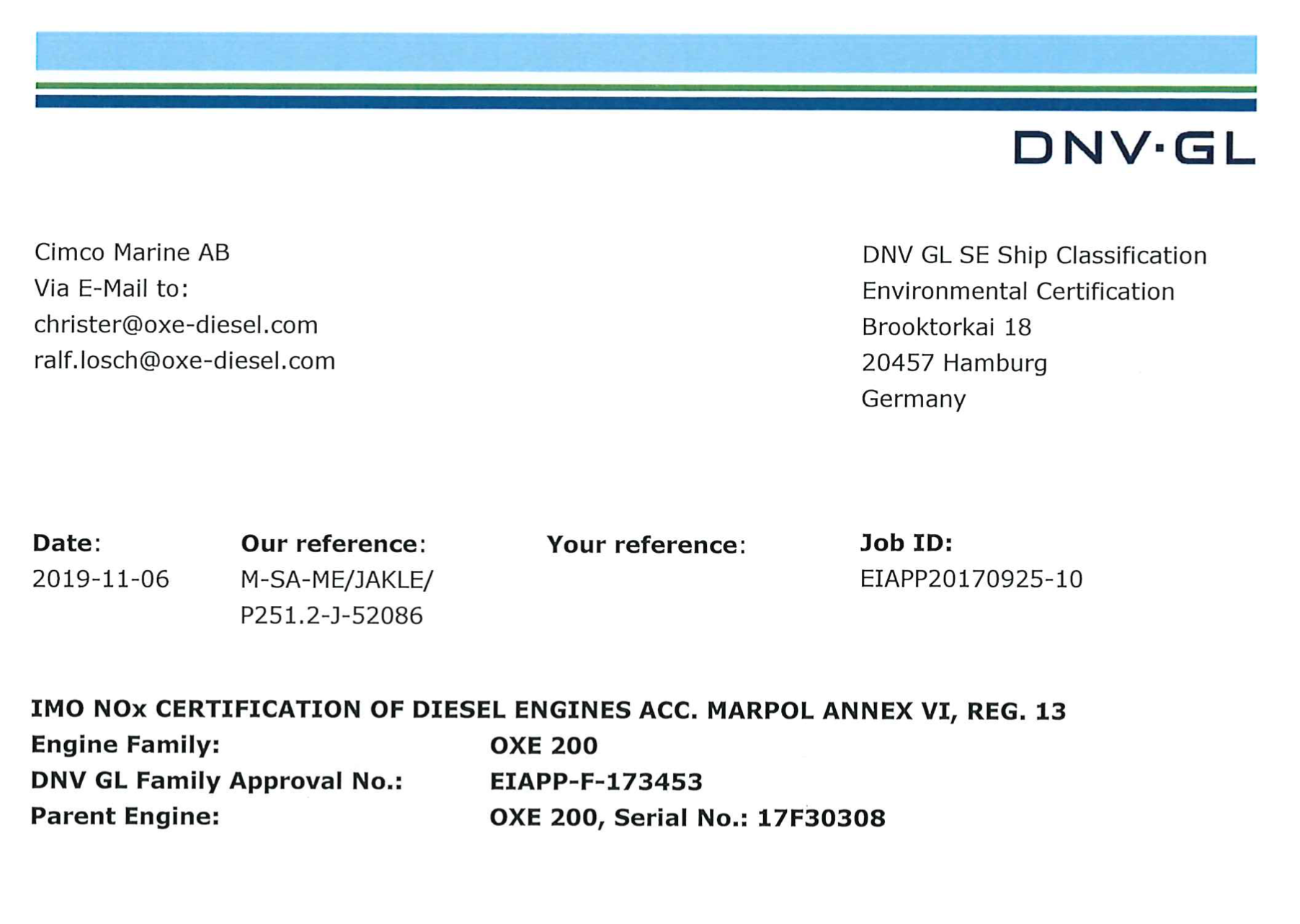

All OXE Diesel models comply with stringent EPA Tier-III, IMO Tier II and RCD emissions and environmental standards. The diesel outboards are available in:

OXE 125, 125 HP and 376NM (278ft-lb) of torque

OXE 150, 150 HP and 380NM (287ft-lb) of torque

OXE 175, 175 HP and 380NM (287ft-lb) of torque

OXE 200, 200 HP and 415NM (306ft-lb) of torque

OXE 300, 300 HP and 680NM (501ft-lb) of torque

The OXE Diesel offers an effective and safe solution for: governmental, oil & gas, search & rescue and large commercial applications, also for small craft fishermen and fish farmers, survey, tourism, yacht tender, taxi and pilot operations - all applications where range, load carrying performance and running costs are significant factors.

Features

- - Diesel engine

- - Low Speed Control

- - Fuel economy

- - CAN based helm control system

- - Dual helm capability

- - Joystick capability

- - Robust modular design

- - Low drag propulsion housing

- - Directly replaceable with other outboards

- - Quick shift capable

Leading innovations

Leading innovations

The OXE Diesel is specifically designed to increase endurance, reliability, power and control of marine outboards. The modular design and patented belt transmission make it possible to move away from general-purpose products, built for sunny days and pleasure craft users and offer a more robust solution built for commercial applications operating in the fiercest conditions. Commercial users can now move towards a safer product that is designed to last and built to rise to the tasks at hand. The time of the world’s first high-performance outboard engine, the OXE Diesel is here.

Innovation has long been required to fill this demand for the commercial marine market. A product that combines the flexibility of the pleasure craft outboards and reliability of inboards/sterndrives, that:

- - Reduces fire hazard

- - Enables refilling from on-water platforms and vessels

- - Increases serviceability

- - Increases operational range.

Due to the above demands, the team behind the world´s first high-performance diesel outboard based the OXE Diesel on a modern diesel powerhead from the automotive industry. The use of state-of-the-art diesel engines further escalated the demand on the power train. The team quickly realized that the bevel gear systems found in traditional inboard and sterndrive power trains, with vertical shafts and dog-clutch are neither designed for nor able to cope with, high torque or long hours demanded by commercial marine applications.

The team behind the OXE Diesel combined innovation with proven robust design and created the world’s first high-performance outboard. The OXE Diesel combines the reliability of inboard engines with the flexibility and replaceability of outboard engines.

The name1

A NAME FOR ALL SIGNIFICANT ATTRIBUTES

OXE, pronounced ['əʊ, 'eks, 'i:], is the Swedish name for OX. The name reflects the fundamental characteristics from which this product has been developed – endurance, reliability, power, control – all essential attributes for a commercial marine engine.

Using OXE Diesel as the product name also pays tribute to the hard work, stubbornness and relentless effort the team from OXE Marine AB has spent to fulfil the demands of the commercial marine market, applying them to a product worthy of end-user trust.

The OXE Diesel is designed to withstand the punishing conditions experienced in commercial marine environments. Stress tests on hulls used by the Swedish Coastguard have shown that engines in their high-speed boats are regularly exposed to forces of up to 7G. In order to withstand these kinds of forces, the product must be robust and have strength – just like an OX.

Key advantages

Key advantages

Diesel

The common rail turbocharged diesel engine provides high efficiency and torque. This results in powerful thrust and acceleration, with the capacity to carry heavy loads.

The engine runs on a large variety of fuels: EN 590, ASTM D 975 No. 1 and No. 2, JIS KK 2204, F54 and F75.

Environment

The use of highly refined, modern automotive-based engine technology significantly reduces the fuel consumption and provides for industry-leading emission levels and subsequent minimized impact on the environment, significantly reducing not only CO2 but also CO1, HC and NOx - setting new standards for internal combustion engines within the global outboard engine industry.

The emission levels are approved by EPA TIER III, IMO TIER II (MARPOL VI TIER 2), RCD and CCS.

Safety

Diesel is a less flammable fuel and therefore much safer to work within all working environments. Robust design, low-Speed Control and quick-shift capability lead to safe operation in adverse conditions. The OXE Diesel is designed to be safe in any environment.

Maintenance

Easily accessible service points and a modular design create a user-friendly product. Fast interchangeable gear ratio allows for specific performance requirements. The reliable automotive powerhead keeps costs of maintenance and spare parts low. Longer service intervals ensure fewer disruptions in engine usage, increasing operational profitability and productivity.

Range

Due to significantly lower fuel consumption than a comparable modern outboard, the OXE Diesel offers the market unprecedented range, enabling users to not only reach further but also giving the ability to refuel from larger diesel-powered vessels or marine-based platforms.

Performance

Performance

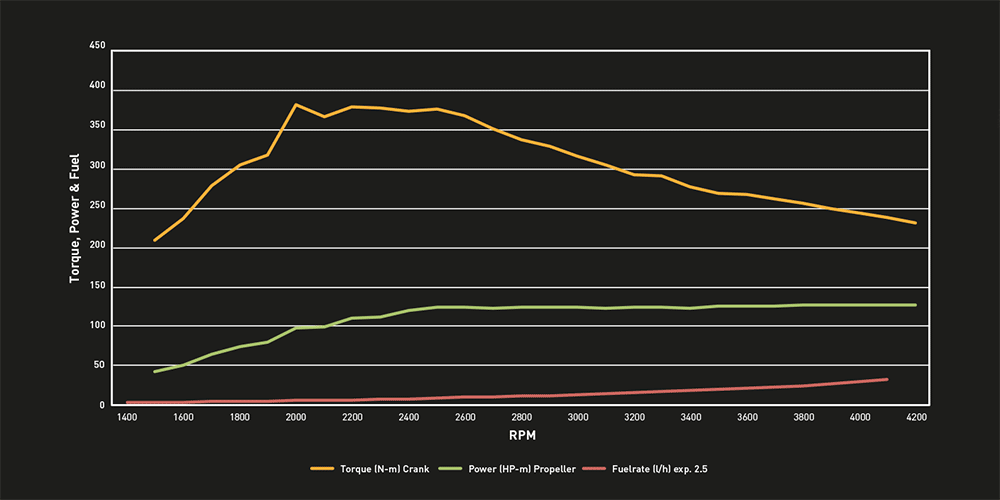

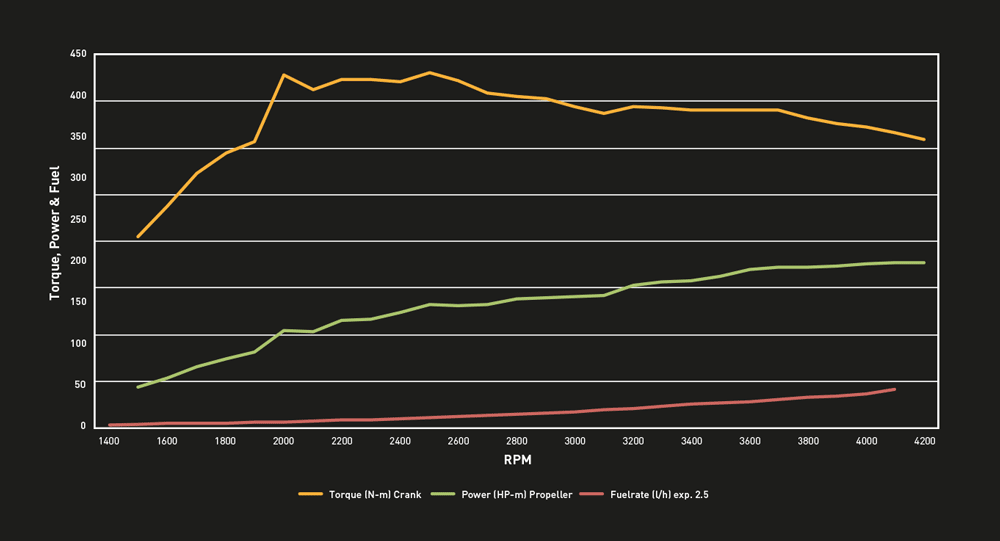

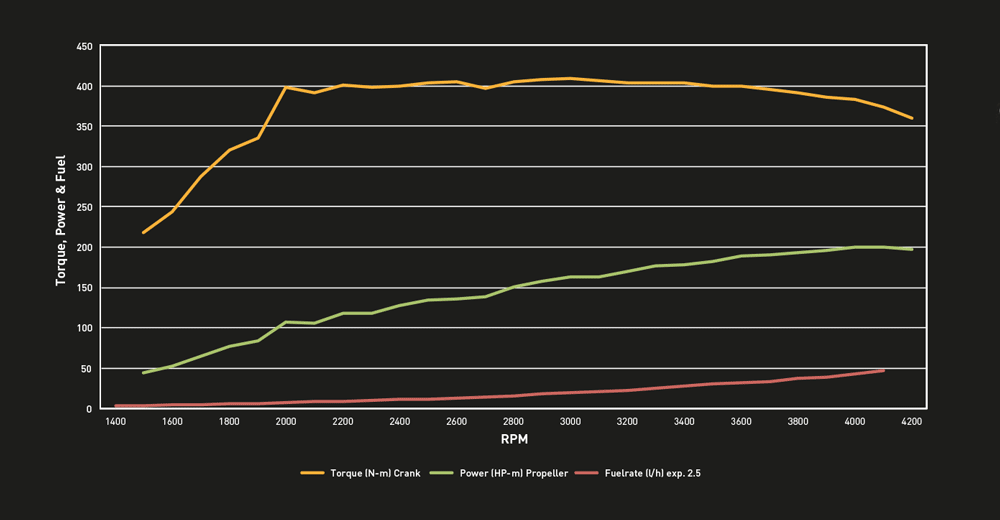

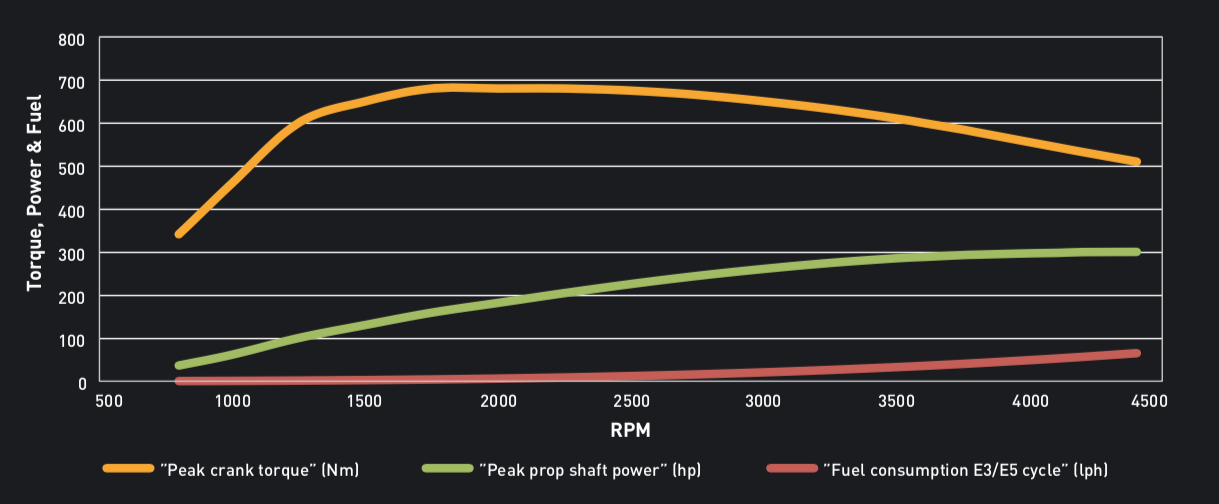

ENGINE PERFORMANCE

The OXE Diesel has been optimized for commercial usage. Significant effort has been put into reducing life cycle costs and maximizing the potential range to allow the users to go further. It is built to provide the solution for governmental, rescue, military, fishing and other commercial applications.

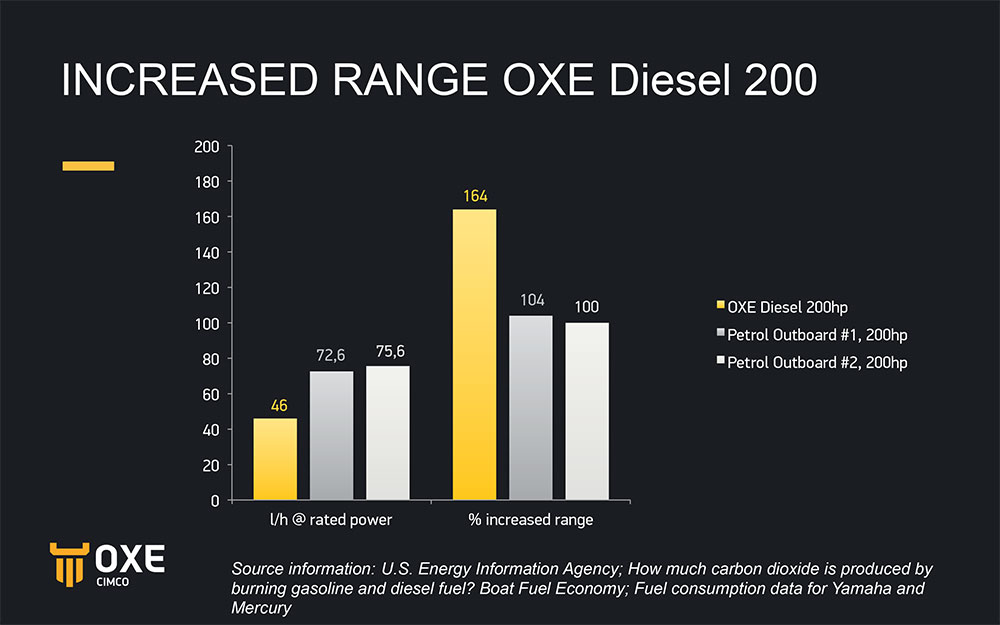

Diesel provides higher efficiency and torque, which gives increased load capacity and greatly reduced fuel consumption compared to petrol, resulting in up to 60% increased range. Diesel is less flammable than petrol and therefore much safer to work with, contributing to significantly reduced fire hazard and a safer working environment.

The combined benefits of an efficient modern Diesel Engine and the robust transmission deliver unique benefits for durability and increased range of commercial operation.

Simon Hill, Western Mariner described his experience as follows:

“In use, the Oxe diesel outboards distinguish themselves by being mostly indistinguishable from the well-proven and well-loved gas-powered outboards most mariners are familiar with. Because they have a fairly deep exhaust note, at idle the OXE diesel outboards can actually seem some-what quieter than a gas outboard. At higher revs and wider throttle settings, they have a distinctive muffled growl that’s been compared to the Dark Knight-era Batmobile.”

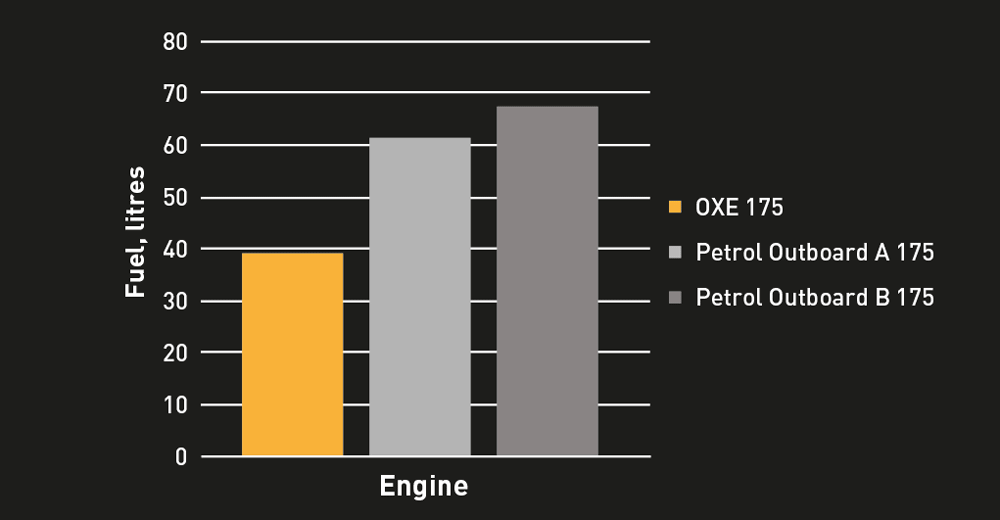

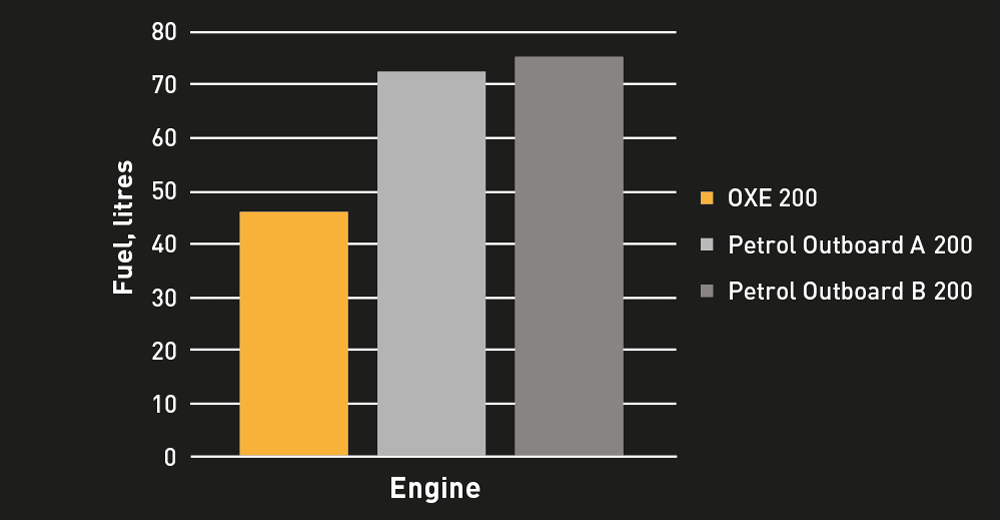

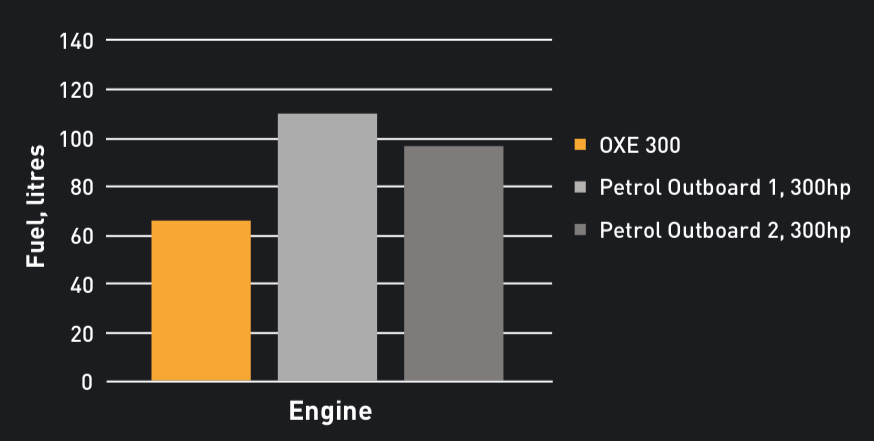

Fuel economy

OXE DIESEL CONSUMES UP TO 42% LESS FUEL

The price of fuel is having a major affect on the marine market in both price and accessibility. As motor boats have a poor fuel economy compared to road vehicles, a decrease in fuel price contributes to a significant reduction in the running costs for boat operators.

The OXE Diesel power head is a well-proven diesel engine designed by the automotive industry. As the OXE Diesel design raises the gearbox above the water line it allows for a slimmer design under the waterline. This design is optimized for reducing drag thus reducing the fuel consumption further, increasing range and enabling longer intervals between refueling.

Reduced fuel consumption translates to increased operating range, longer refueling intervals and overall reduced fuel costs. It has resulted in a product with up to 42% lower fuel consumption than a modern pleasure craft petrol outboard of equivalent horse power and giving more than 60% increased range.

Tony Kortens from Landing craft UK LTD states: "The OXE is faultless; the smoothness; power; and thrust of the engines are amazing. We can achieve speeds of 20 knots in a boat that weighs in excess of ten tonnes. The OXE’s excellent fuel economy shows with all three engines running to their maximum we have a fuel burn of 90 liters per hour which is phenomenal."

.jpg)

Technical data - OXE Diesel

| Engine type: | Diesel, L4 |

| Displacement: | 2.0 L |

| Intake: | Turbocharged, intercooled |

| Torque: | 415 Nm at 2500 rpm |

| Power: | 200 HP at 4100 rpm |

| Fuel: | Diesel |

| Weight: | 350 kg |

| Alternator output: | 130 Amp |

| Rig length: | 25” or 33” |

| Cooling: | Closed cooling circuit |

| Starting: | Electric |

| Steering: | Electronic Power Steering |

| Shiſt: | Electro-hydraulic |

| Clutch: | Hydraulic multi-friction plate |

| Gear ratios: | 1.73:1 and 2.17:1 |

| Dimensions (25” leg), LHW | 994x1880x678mm |

Quick shift capability

QUICK SHIFT CAPABILITY

The OXE Diesel features Quick Shift Capability and Low Speed Control (LSC), revolutionary systems that enable unprecedented control while towing, mooring or maneuvering. The Quick Shift and LSC are made possible through an electro-hydraulically operated clutch system that ensures smooth shifting between neutral, forward and reverse.

The quick shifting allows the user to run the engine in forward gear and throw it directly into reverse without breaking the gearbox. The electronics for the engine will automatically rev down to a certain level before it switches to reverse, reducing the need for evasive maneuvers that risk tearing gearboxes apart.

Simon Hill, Western Mariner states that: "Because the engine is fresh-water cooled with a built-in heat exchanger, the Oxe outboard allows easy addition of a bus heater connection at the bypass circuit. And because the transmission is an electro-hydraulic multi-plate clutch design, it not only provides smooth shifting and crash-stop protection, but also provides a built-in low speed trolling mode that eliminates the need for (and costs associated with) a separate trolling motor."

Significant operational benefits

SIGNIFICANT OPERATIONAL BENEFITS

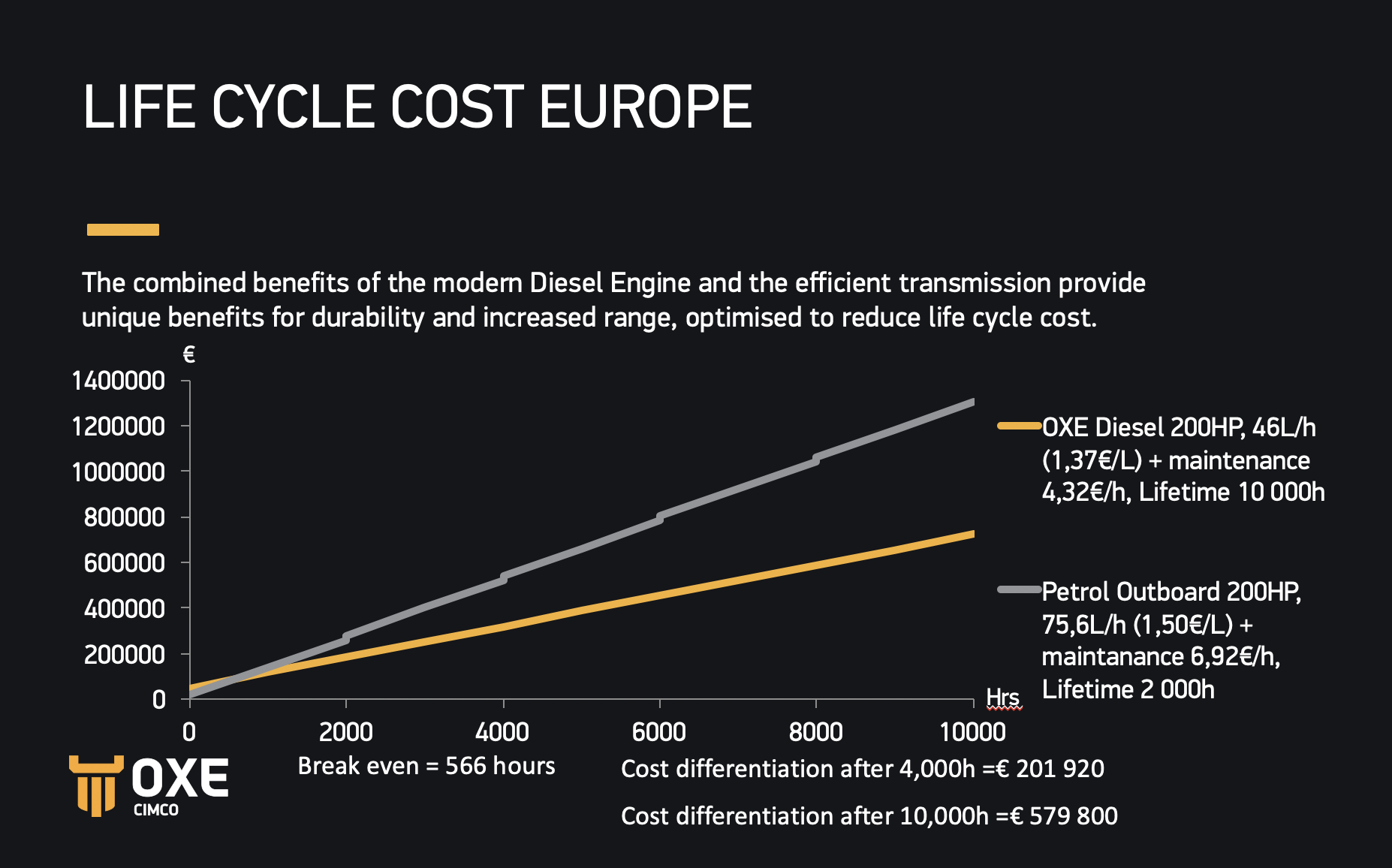

The OXE Diesel is designed to last. Accessible service-points and longer service intervals lead to lower maintenance costs and longer operation times. Longer TBO results in life cycle costs that are kept at a minimum whilst time on the water remain high. The combined benefits of the modern Diesel Engine and the efficient transmission provide unique benefits for durability and increased range, optimized to reduce life cycle cost.

Diesel is often required on safety grounds as workboats and landing crafts work alongside fire regulated structures e.g. Liquid Natural Gas (LNG) jetties and also because the supply of petrol is becoming increasingly limited. The OXE Diesel is the first approved high-performance diesel outboard.

The UK marine distributor Proteum has supplied three OXE Diesel 150 engines to Landing Craft UK (LCUK), safety and workboat specialists, who built the landing craft for GPSM DiveCo Ltd.

Tony Kortens, MD of Landing Craft UK Ltd, said, “The OXE is faultless; the smoothness; power; and thrust of the engines are amazing. We can achieve speeds of 20 knots in a boat that weighs in excess of ten tonnes. The OXE’s excellent fuel economy shows with all three engines running to their maximum we have a fuel burn of 90 litres per hour which is phenomenal”.Jeremy Paul, General Manager of Proteum, said, “Commercial operators have been wanting a high-performance diesel outboard for a very long time to benefit from diesel’s lower maintenance and longer service life. OXE has solved this need, proved its reliability and is ready to go!”.

In addition to workboats, the OXE diesel is suitable for coastal fishing, aquaculture, ferry operations, survey work, emergency services and other security and defence-related operations.

Diesel has a higher working efficiency than petrol and OXE uses up to 40% less fuel than a modern 4-Stroke Outboard. The OXE Diesel also has an extended range, significantly increasing the operational time between refuelling.

Bjørn Toni Bakken, who has installed twin OXE diesel on an Aluventure 1100XE states: “After driving my boat with 2 x 200 HP OXE for over 400 hours this year I am very pleased with this innovative product! My main reason for selecting OXE was the lower consumption and long service intervals, but I am equally impressed by the low dB and how smooth the gearbox is, especially since I use joystick to maneuver a lot. Thumbs UP!”.

Service interval

200 h

Extended service

2000 h

Life cycle cost

OPTIMIZED TO REDUCE LIFE CYCLE COST

OXE Diesel contributes to the combined benefits of the modern diesel engine from the automotive industry and an efficient transmission that provides unique benefits for endurance, reliability, power, control, increased safety and range, optimized to reduce life cycle cost.

Simon Hill, Western Mariner states "At the heart of the Oxe diesel outboard is a marinized 4-cylinder GM turbodiesel automotive powerplant. As with any marine diesel engine, it provides the advantage of a safe, inexpensive fuel source, with the added advantage of allowing single-fuel requirements for companies running a diesel-powered fleet. High torque provides performance that’s equivalent to a slightly higher-horsepower gas-powered outboard".

Break even = 566 hours

Cost differentiation after 4,000h =€ 201,920

Emissions

Emissions

MADE FOR LOW EMISSIONS

Throughout the development process of the OXE Diesel the goal was to develop and implement technologies and strategies to provide engines that meet the most stringent standards in exhaust, noise and vibration emissions.

The OXE Diesel models are compliant with the emission regulations established by the Environmental Protection Agency (EPA), European Union (EU), the California Air Resources Board (CARB) and for OXE175 and OXE200 the EIAPP. It is also compliant with IMO Tier II, EPA Tier III and RCD.

OXE diesel compliance with emissions regulations.

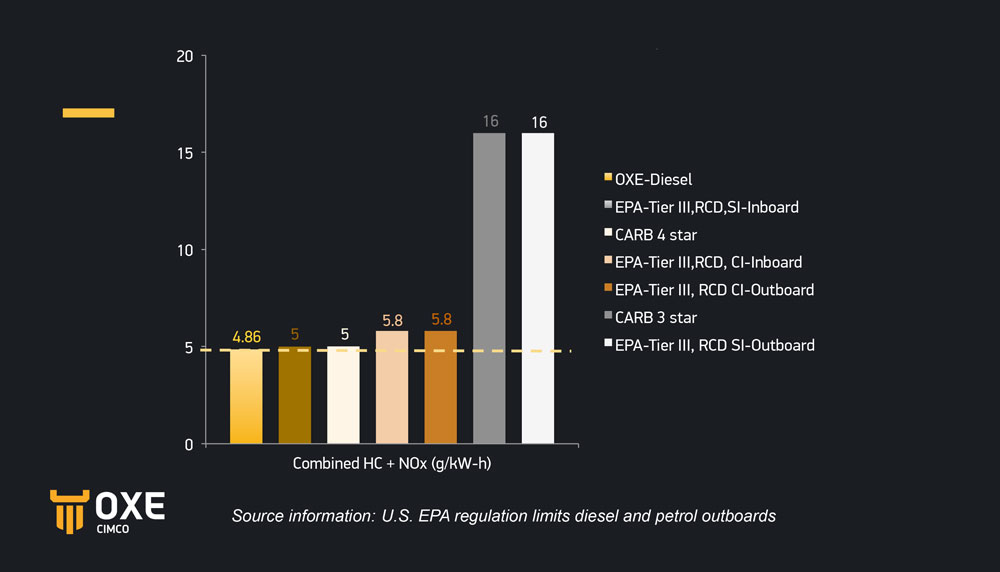

Emissions regulations (HC + NOx)

EMISSIONS REGULATIONS (HC + NOX)

Source information: U.S. EPA regulation limits diesel and petrol outboards

The EPA and EU are at the forefront for establishing the most stringent standards in effect today. Exhaust performance and testing requirements put the responsibility on the manufacturer to design and establish the most advanced engine control technology available.

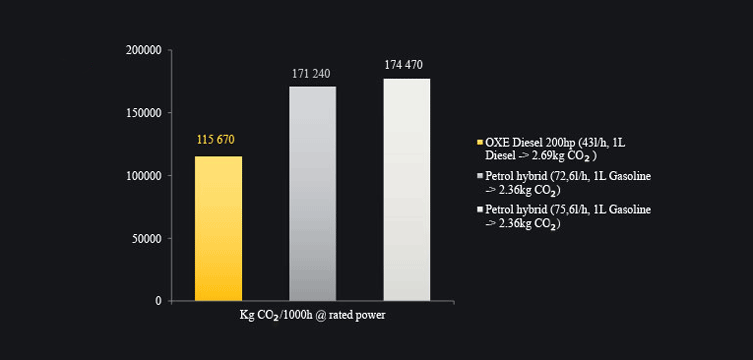

CO2

CO2 EMISSIONS

The reduced fuel consumption is a key factor to why the OXE Diesel engine emits significantly lower CO2 than petrol outboard engines. 1L Diesel produces approximately 2.69kg and 1L petrol produces 2.36kg CO2 when ignited. However, as the OXE Diesel consumes up to 42% less fuel than comparable petrol alternatives, the OXE Diesel reduces the CO2 emissions by up to 35.5%

Reduced emissions CO2

Source information: U.S. Energy Information Agency; How much carbon dioxide is produced by burning gasoline and diesel fuel? Boat Fuel Economy; Fuel consumption data for Yamaha and Mercury.

CO1

REDUCED FUEL CONSUMPTION FOR LOWER CO1

The reduced fuel consumption, is a key factor to why the OXE Diesel engine emits significantly lower CO1, when comparing the OXE Diesel to pleasure craft petrol outboards.

Regulations in the EPA Tier III directive have forced the automotive industry to reduce these emissions. As the OXE Diesel power head is derived from the automotive industry this impact transcends down. In accordance to EPA Tier III, 1L of diesel should only emit 8,36g while the non-regulated petrol engines can emit up to 620g/L

This result in a reduction of CO1 by up to 99,7%

Reduced emissions CO1

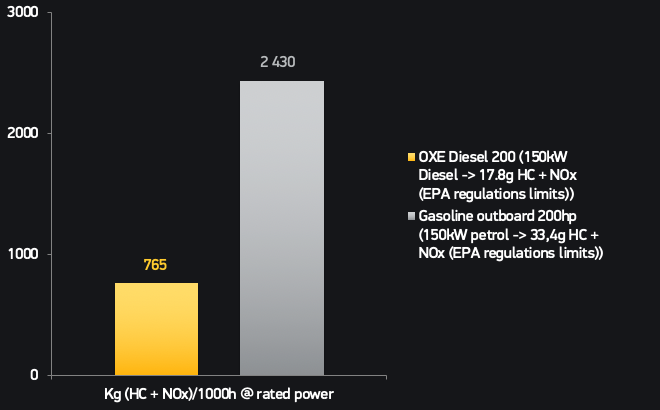

HC+NOx

HC+NOX

The reduced fuel consumption is a key factor to why the OXE Diesel engine emits significantly lower HC and NOx than petrol outboard engines. 1L of diesel produces approximately 17.8g compared to 1L of petrol which produces 33.4g HC+NOx when ignited.

As OXE Diesel consumes up to 42% less fuel than comparable petrol alternatives the OXE Diesel reduces the HC+NOx emissions by up to 69.8%.

Reduced emissions (HC + NOx)

Source information: U.S. EPA regulation limits diesel and petrol outboards

The Design

The Design

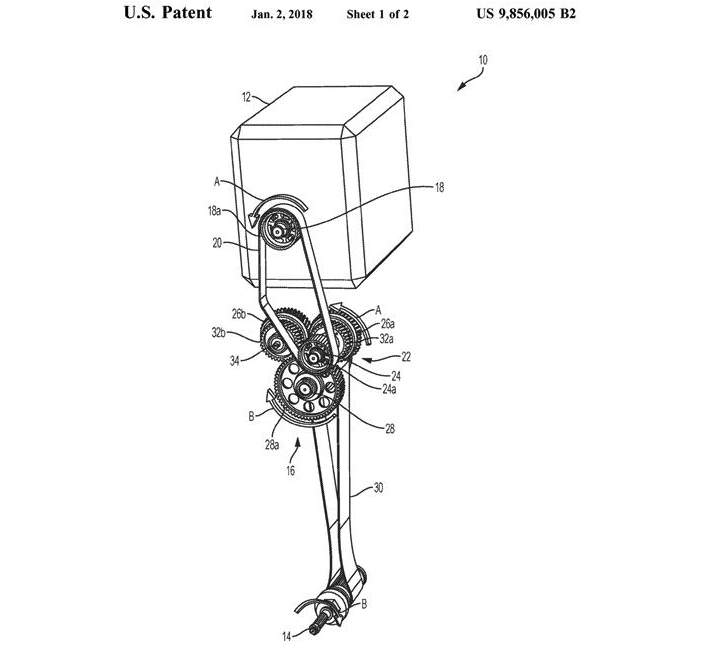

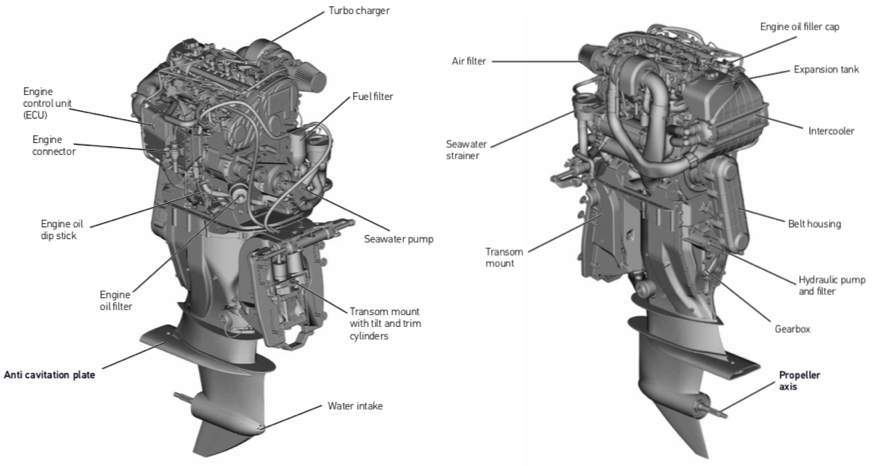

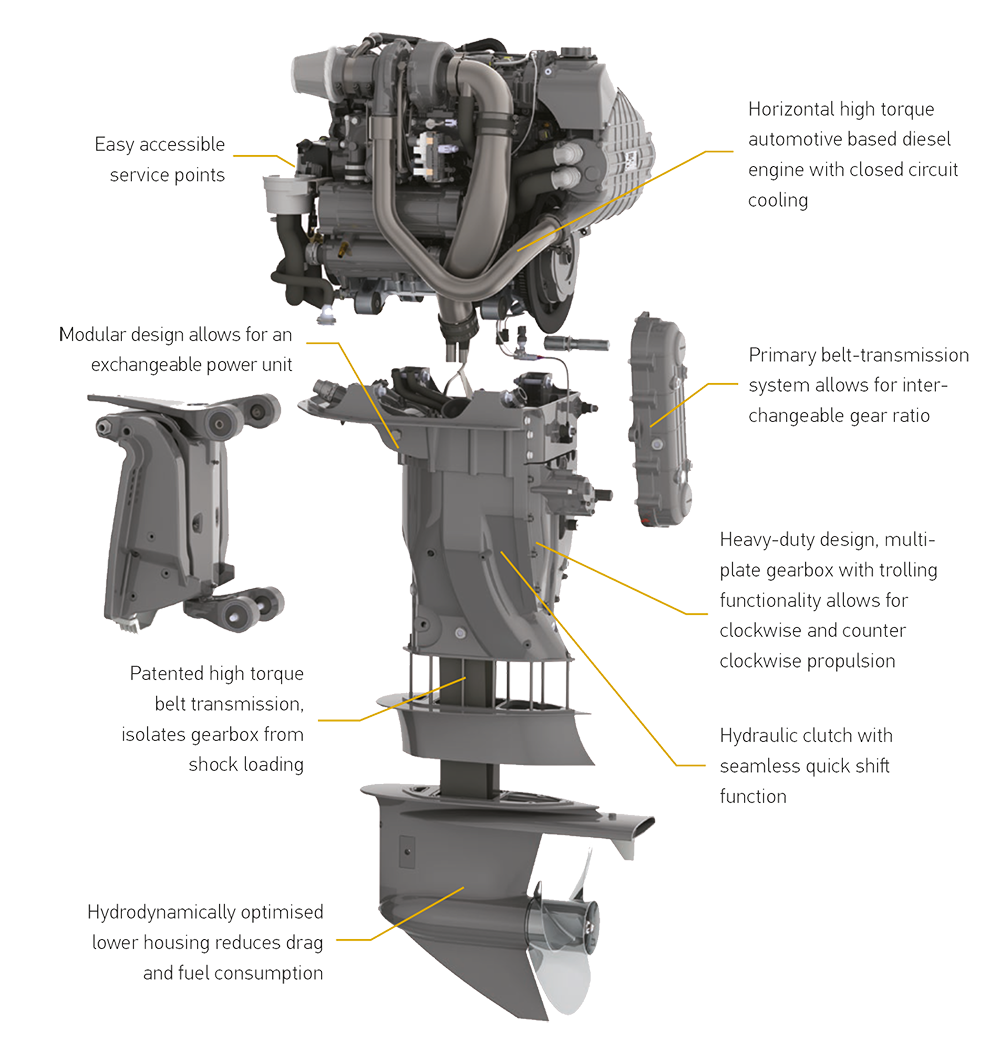

UNIQUE DESIGN

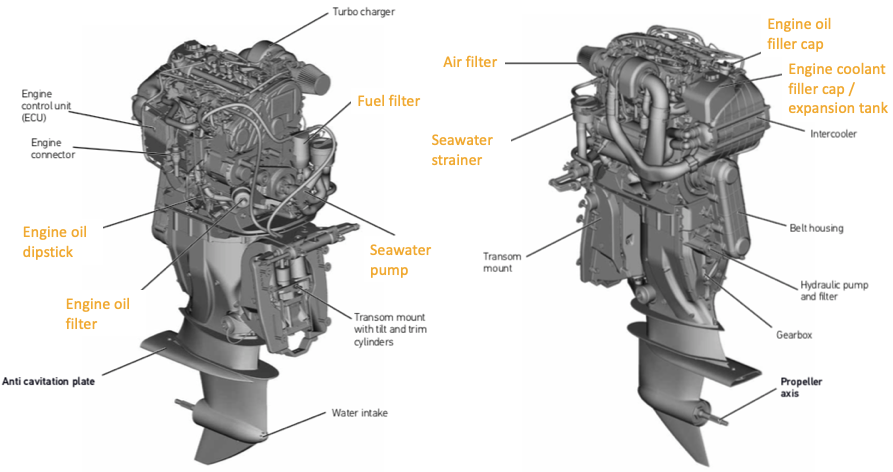

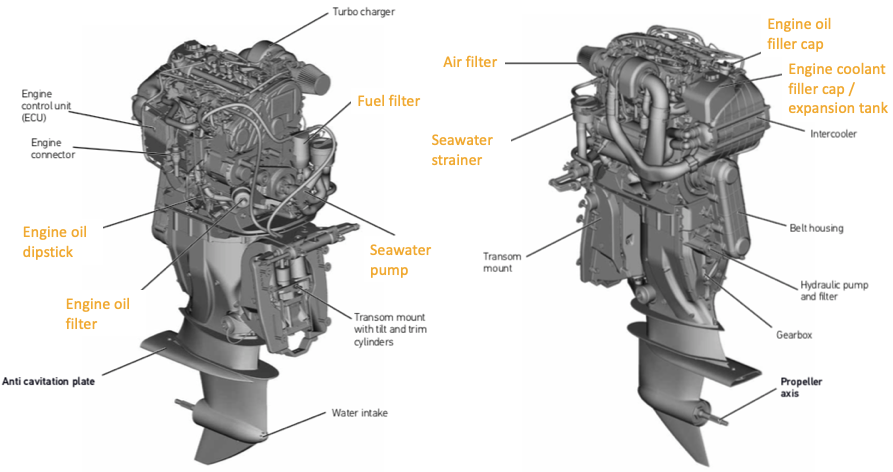

The diesel engine on the OXE Diesel has been adopted from the automotive industry. In relation to a vertically mounted outboard engine, a horizontally mounted engine reduces wear and improves heat dissipation. The power is transferred to the gearbox through the primary belt which can be positioned in either high speed or high torque setting. From the gearbox output a second belt transfers the power directly to the propeller shaft, eliminating the need for a conventional bevel gear system completely.

The patented OXE Diesel system has revolutionized the outboard engine markets dependence on a traditional outboard drive system, eliminating the need for antiquated, vulnerable and inefficient dog clutch and bevel gear systems. Not only does the robust design of the OXE Diesel facilitate the high torque transfer of a diesel engine where conventional drive systems could fail, the OXE Diesel presents the end-user with a product specifically built for arduous working conditions.

The idea behind the design

OUR IDEA WAS TO MAKE SOMETHING GREAT

The reduced fuel consumption is a key factor to why the OXE Diesel engine emits significantly lower HC and NOx than petrol outboard engines. 1L of diesel produces approximately 17.8g compared to 1L of petrol which produces 33.4g HC+NOx when ignited.

At the beginning of the OXE Diesel project, our mission was to design the world’s first high performance diesel outboard, built specifically for the commercial user. The idea was to combine inboard reliability and diesel torque with the flexibility and replaceability of an outboard unit.

From an early stage the keywords were endurance, reliability, power and control. These words became embedded in the development and thereby into the very being of the OXE Diesel. The result of this is apparent in the modular design of the OXE Diesel product range.

Combining a modular layout with proven technologies (engine, gearbox, belt systems) has created an extremely durable product that is easy to work with both from a users and mechanics perspective.

The patented belt technology enabled the team to design a robust outboard unit that effectively transfers high torque from automotive or industrial diesel engines to the propeller with minimal transfer loss.

From decades of experience within diesel engines and transmissions, the team aimed for quality and state-of-the-art design. This, together with leading Swedish manufacturers from the marine, automotive, commercial and aeronautical industry, has given the OXE Diesel a winning concept.

- - Use of horizontal automotive diesel engine with a proven design

- - Belt transmission from engine to gearbox with interchangeable gear ratio

- - Use of electro-hydraulically controlled gearbox

- - Patented high torque belt drive

- - Directly replaceable with outboard units in the same power range

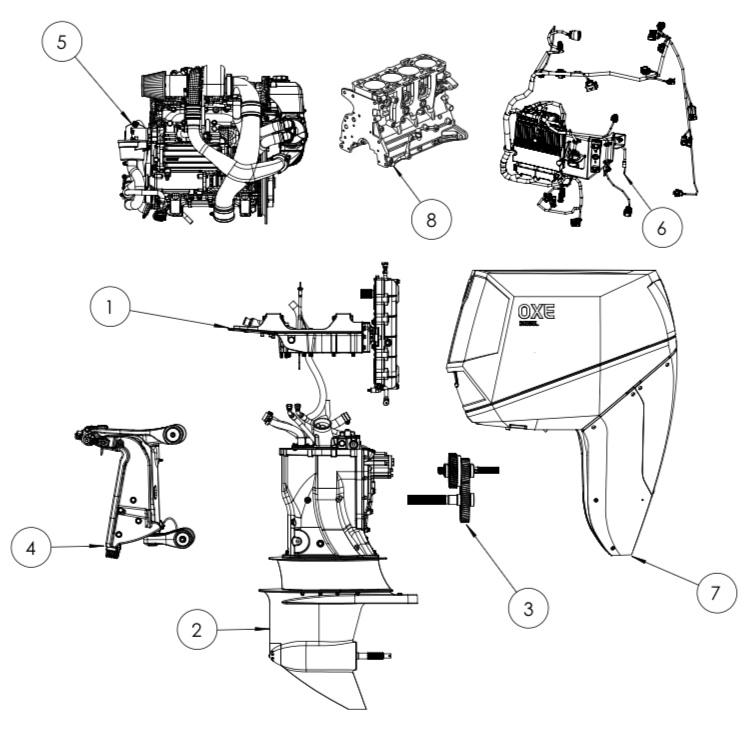

1. Upper housing assembly, 2. Lower leg assembly XL / XXL, 3. Gearbox assembly, 4. Transom mount assembly, 5. Marine engine assembly, 6. Electric system, 7. Cowling assembly, 8. Internal engine parts

Each part has its place

EACH PART HAS ITS PLACE

The diesel engine on the OXE Diesel is mounted horizontally; the power is then transferred to the gearbox through a primary belt. From the gearbox output a second belt transfers the power to the propeller shaft.

The engine is mounted on the adapter plate with four robust anti-vibration mountings to allow the unit to endure punishing commercial use and also to be quickly and easily replaced.

By using a modular design, the OXE has been built from the ground up with proven conventional technology.

All parts are easy to access and can be changed without having to disassemble the whole unit. Each part has its place.

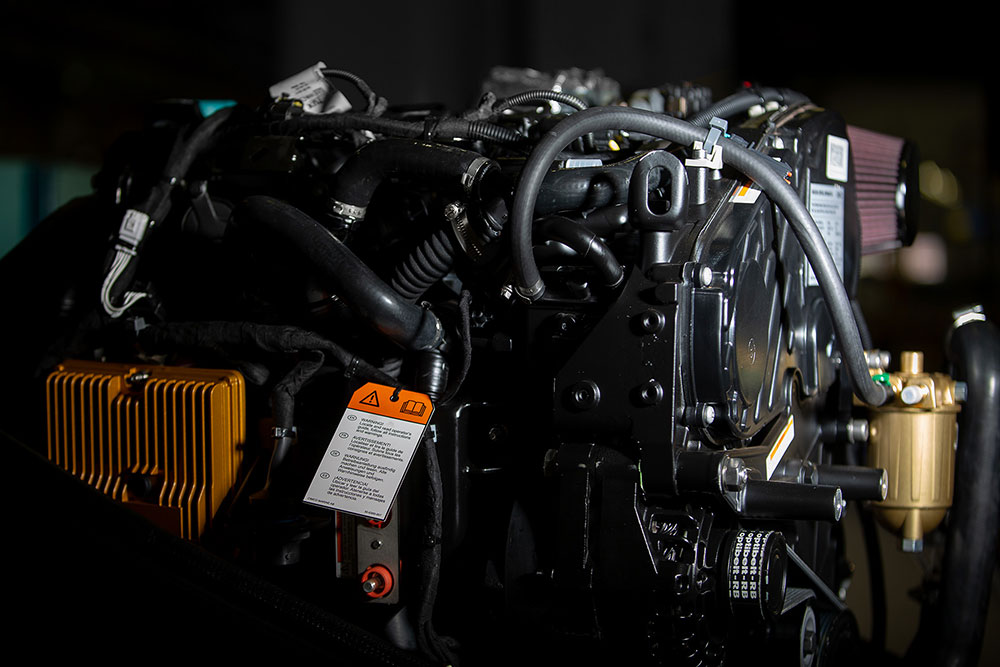

Diesel Engine

Diesel Engine

THE DIESEL ENGINE

The power head of the OXE Diesel is a proven, robust diesel engine developed by GM group. It is mounted horizontally and marinized with a closed circuit coolant system inspired by modern inboard technology.

It allows for a high output alternator and cabin heat, which often is requested by users in cold weather operations and power demanding equipment. All service points have been positioned toward the deck side of the unit for easy maintenance and service.

Automotive-inboard technology

INDUSTRY LEADING EMISSION LEVELS

The GM engine has been converted for marine application by using separate systems for seawater, heat exchangers, intercooler and oil cooler and functionality that ensures that the engine, electrical system, fuel system and air intake withstand marine conditions.

The use of highly refined automotive based engine technology provides for industry leading emission levels.

The advantage of Diesel

WHY DIESEL IS GREAT FOR OUTBOARD ENGINES

Diesel is a less flammable fuel and therefore safer to work with in hazardous environments. Diesel also provides higher efficiency and torque, ensuring enhanced acceleration and lower fuel consumption.

The reduction in fuel consumption increases range, facilitating extended operational periods and increasing time duration between refueling.

The engine runs on EN 590, ASTM D 975 No. 1 and No. 2, and JIS KK 2204, F54 and F75 which provides end users with high flexibility.

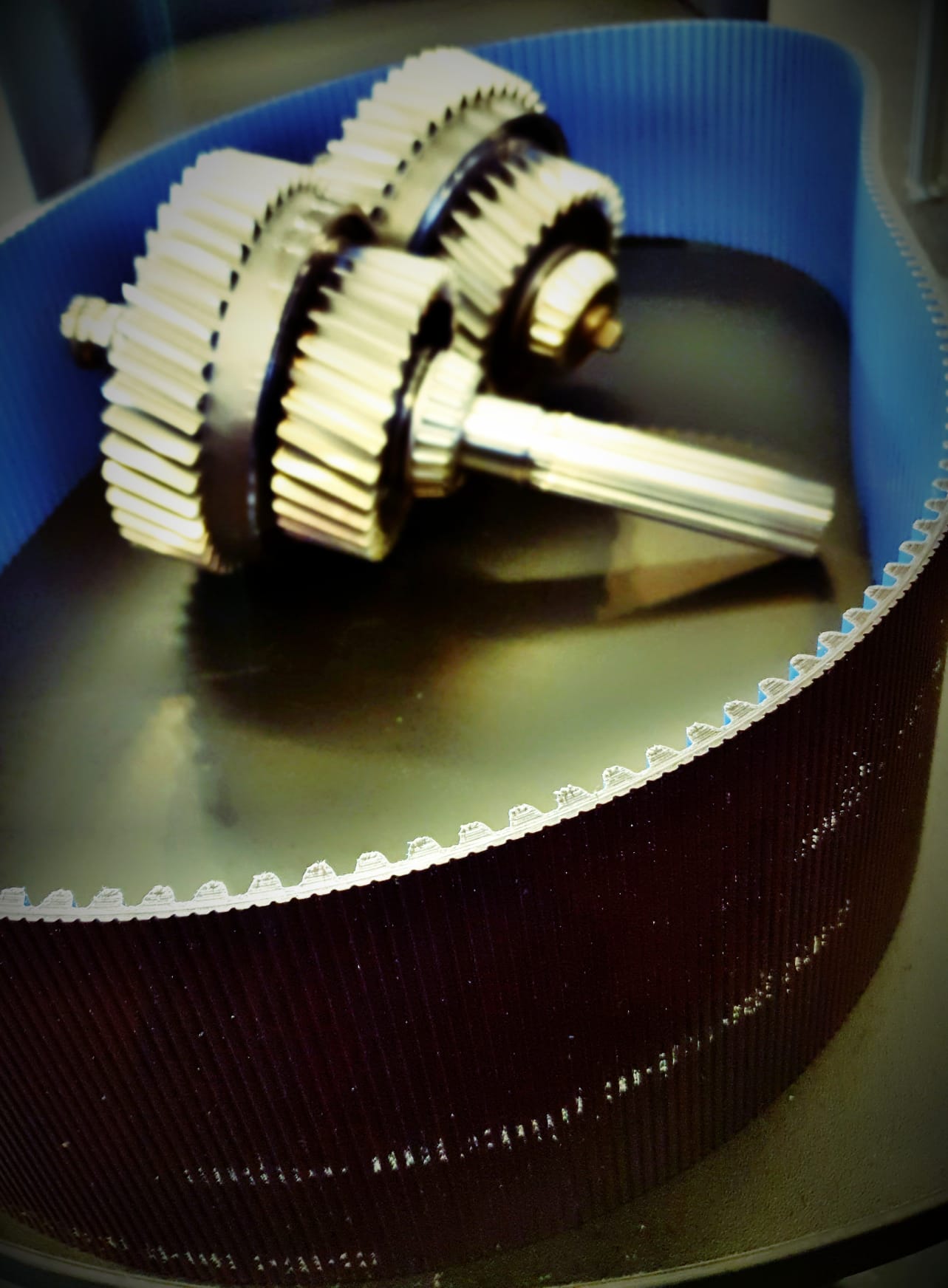

Transmission

Transmission

THE TRANSMISSION

The patented belt drive allows full range torque transfer capability without affecting the hydrodynamics of the OXE Diesel. The belt transmission technology provides solutions in outboard form that have been until now exclusive to inboard applications.

Simon Hill, Western Mariner states that: "Because the engine is fresh-water cooled with a built-in heat exchanger, the Oxe outboard allows easy addition of a bus heater connection at the bypass circuit. And because the transmission is an electro-hydraulic multi-plate clutch design, it not only provides smooth shifting and crash-stop protection, but also provides a built-in low speed trolling mode that eliminates the need for (and costs associated with) a separate trolling motor."

Primary belt

FLEXIBLE GEAR RATIO TO FIT VARIOUS DRIVING STYLES

The primary belt system provides the user with the ability to change the gear ratio of the unit to fit various demands and driving styles. Depending on the needs of the operator, high torque or high speed can be selected. It's designed as a separate unit that is easily reversible. By switching orientation of the primary belt housing, the user can change the gear ratio between 1.73:1 and 2.17:1.

Gear box

GEAR BOX DESIGNED TO WITHSTAND CRASH STOPS

The gearbox is mounted separately under the power head but above the waterline. It is thereby protected from damage if the unit runs aground. The gearbox is a robust electro-hydraulically operated system with two multi-plate-clutch packages that allow for high torque and power transfer.

It is designed to withstand crash stops and operates both clockwise and counter clockwise to allow the user to mount or even transfer the OXE Diesels on any boat and between different configurations. Propeller rotation is simply selected from the display settings.

1. Input shaft assembly, 2. Output shaft assembly, 3. Reverse gear assembly

OXE Diesel gearbox assembly

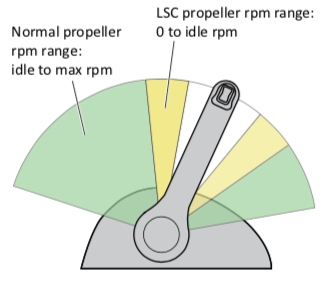

Low-speed control

OUTSTANDING LOW-SPEED CONTROL

The OXE features Low Speed Control (LSC), a revolutionary system that enables unprecedented control while mooring and low speed maneuvering. LSC incorporates an electro-hydraulically operated clutch that ensures smooth shifting between neutral, forward and reverse.

LSC features sensor controlled propeller speed, allowing for seamless control from zero to maximum rpm. The boat is fully operable even below 3-4 knots.

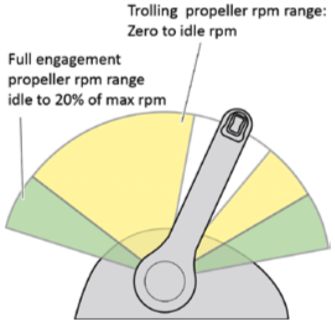

The OXE Diesel also allows for trolling. When engaging Trolling Mode (TM) the full throttle range represents 20% of normal throttle range. This enables a higher resolution of the throttle maneuvering thus giving the operator a more precise control in demanding situations.

OXE Diesel trolling - for fishing, search and rescue operations and patrolling it sounds like a dream - offering a perfect combination with GPS anchoring systems, but also for those who like boats that are fully maneuverable with a joystick for precise manouvering.

Elimination of bevel gears

ELIMINATION OF BEVEL GEARS

The OXE Diesel transmission is built to transfer the higher torque and power inherent in modern diesel engines that are required by commercial end users. As endurance and reliability are in focus, the use of bevel gear systems found in pleasure craft products, were ruled out. To create a product aimed for commercial market a more durable and efficient solution has been utilized in the OXE Diesel, the belt transmission.

The belt transmission used in the OXE Diesel eliminates bevel gears by harnessing the latest belt technology. It allows for increased torque transfer to the propeller, it also allows for smaller torpedoes and slimmer submerged modules. This provides less drag and thereby reduces fuel consumption and increases speed in comparable gear driven units.

Front and reverse gear and belt to propeller-shaft.

Serviceability

Serviceability

SERVICEABILITY

To meet commercial customer demands the OXE Diesel has been designed with ease of maintenance and service in mind. All service points for daily maintenance checks are located in the front of the engine to make service and maintenance as easy and straight forward as possible, even in the harshest of conditions.

As the OXE Diesel is designed as an outboard package, it is replaceable. Service and overhauls can thereby be performed away from the boat by just replacing the power unit. This increases the time on water for the boats.

As all OXE Diesels are clockwise and counter clockwise, rotating the user is free to place the engine on any side of the back of the boat, reducing the need for spare engines.

Service points

SERVICE POINTS

From the aft of the boat and on the front of the OXE Diesel all service points for service and daily maintenance checks are readily accessible after removing the cowl. The design team of the OXE Diesel has put great effort into making the OXE Diesel the easiest outboard for service daily maintenance checks imaginable.

- - Fuel pump

- - Fuel filter

- - Coolant fill

- - Dip stick

- - Oil fill

- - Oil filter

- - Air filter

- - Seawater impeller

- - Seawater strainer

The Seawater impeller is mounted above the waterline, which means that it is possible to change it from the back of the boat.